HistoryHistory of SWECO in Photos

Shikoku Welding Manufacturing was

established in 1947.

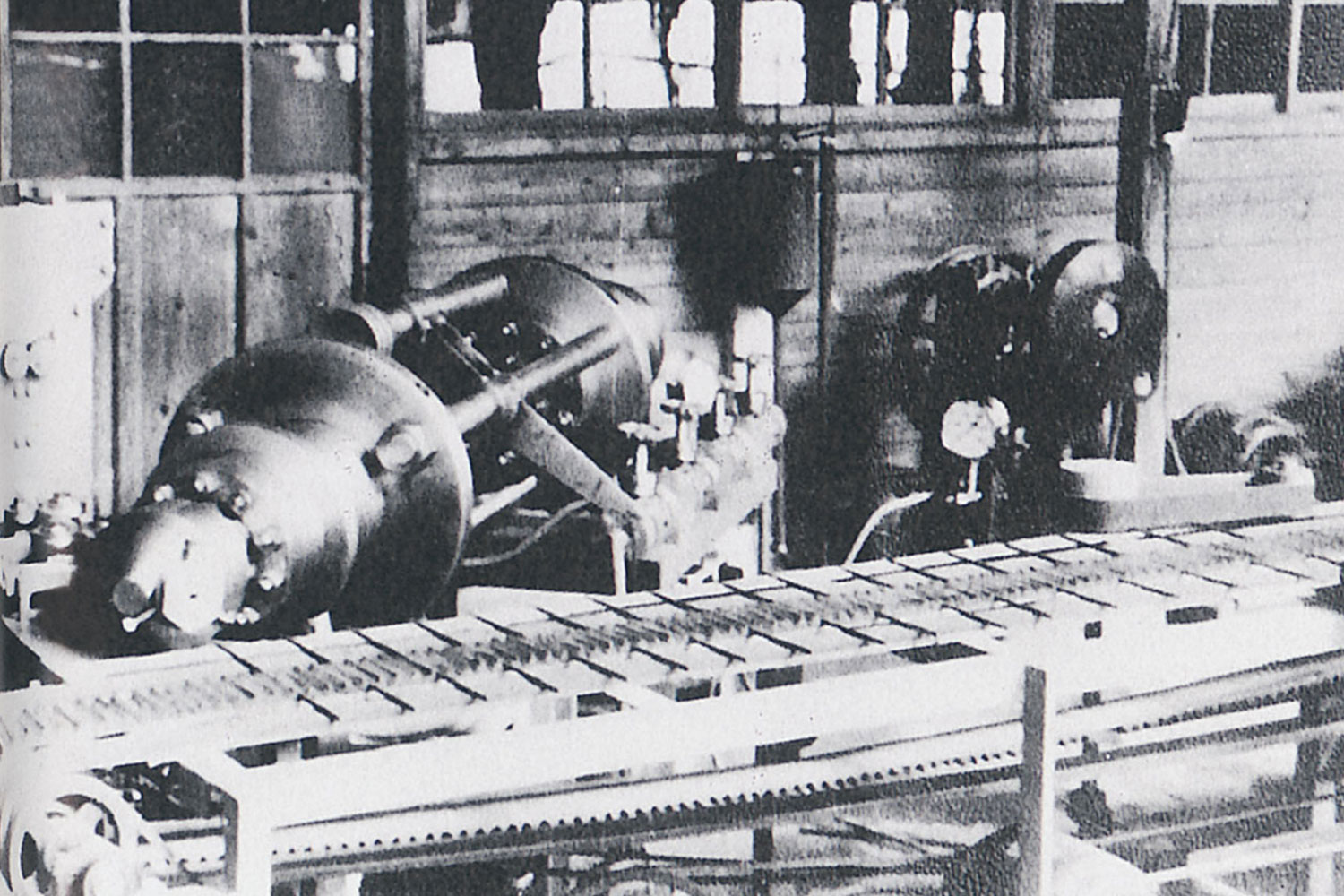

After the war, in order to support Japanese industry, we started as a welding materials manufacturer. The No. 1 automatic electrode coating machine became the foundation for producing our main product, electrodes.

Exterior of plant when the company was founded

No. 1 automatic electrode coating machine

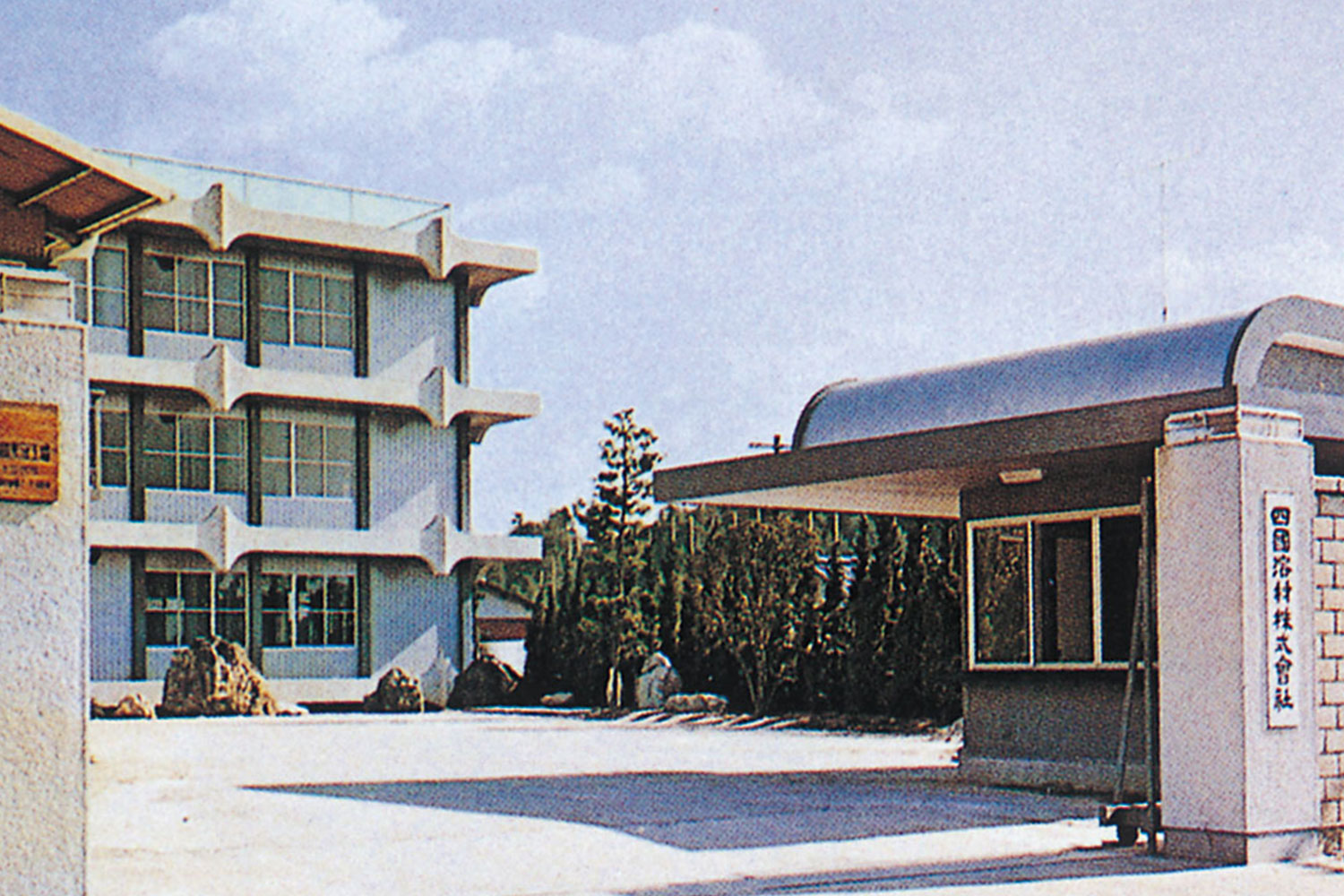

Shikoku Welding Manufacturing front gate

The plant received authorization to display the Japanese Industrial Standards (JIS) mark (JIS Z3211 coated Electrodes for mild steel)

Certification by Nippon Kaiji Kyokai (NK) standards

Completion of new manufacturing plant

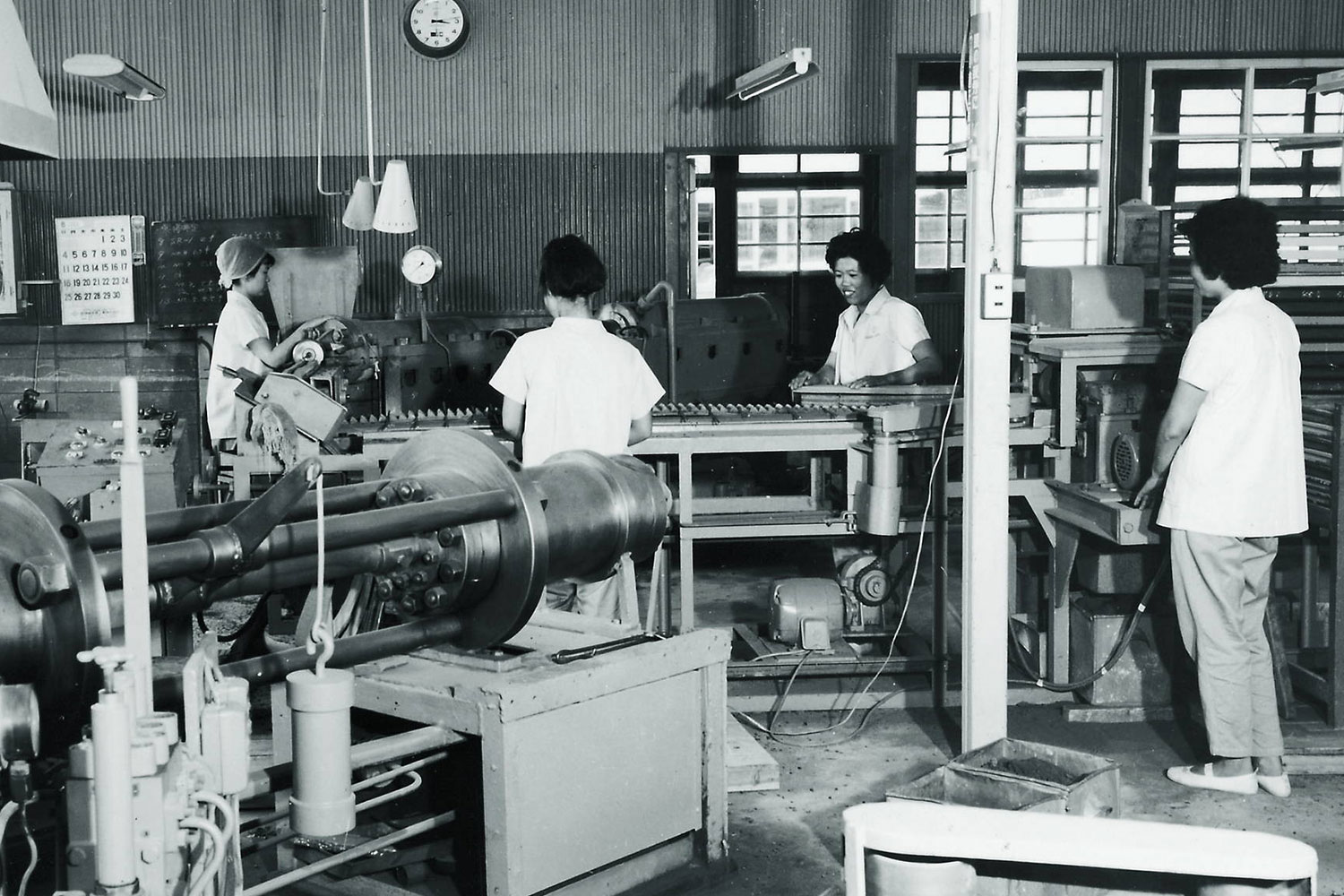

In order to respond to rapidly developing welding demand, we established a new plant in 1958. We created efficient manufacturing and shipping systems.

Plant exterior (1958)

Manufacturing process in the 60s

Packing boxes in the 60s

The company changed shape

In 1963, the company was incorporated and the name was changed from Shikoku Welding Manufacturing to Shikoku Welding Electrode Co., Ltd. We began handling a wide range of services related to welding.

Aerial view of plant (1965)

Headquarters (1968)

Certification by American Bureau of Shipping (ABS) standards

Certification by Lloyd’s Register (LR) standards

Spun off the LP Gas Division and inaugurated Shikoku Youzai Shouji Co., Ltd

Certification by Bureau Veritas (BV) standards

Quality control that brings peace of mind and reliability

The company has been authorized and certified by all kinds of organizations and is progressing with product standardization. We do thorough quality control that makes it possible for anyone to use our products with peace of mind and we are aiming for even more high quality products.

Developed a delivery system using electrode heated containers (1974)

ISO Certification

JIS Certification

Certification of Germanischer Lloyd (GL) standard

The plant received authorization to display the Japanese Industrial Standards (JIS) mark (JIS Z3212 coated Electrodes for high tensile strength steel)

Certification by Norske Veritas (NV) standards

Certified by Korean Register (KR) standards

Certified by Central Research (CR) standards

The plant received authorization to display the Japanese Industrial Standards (JIS) mark(JIS Z3221 Stainless steel coated Electrodes)

Stainless steel coated electrodes certified by Nippon Kaiji Kyokai (NK) standards

Received ISO 9002 quality system standard certification from LRQA

Business expands internationally

In order to respond to globalization, we set up overseas bases. We deliver the typical SWECO quality control system and technological strengths using a new network from Shikoku to the world.

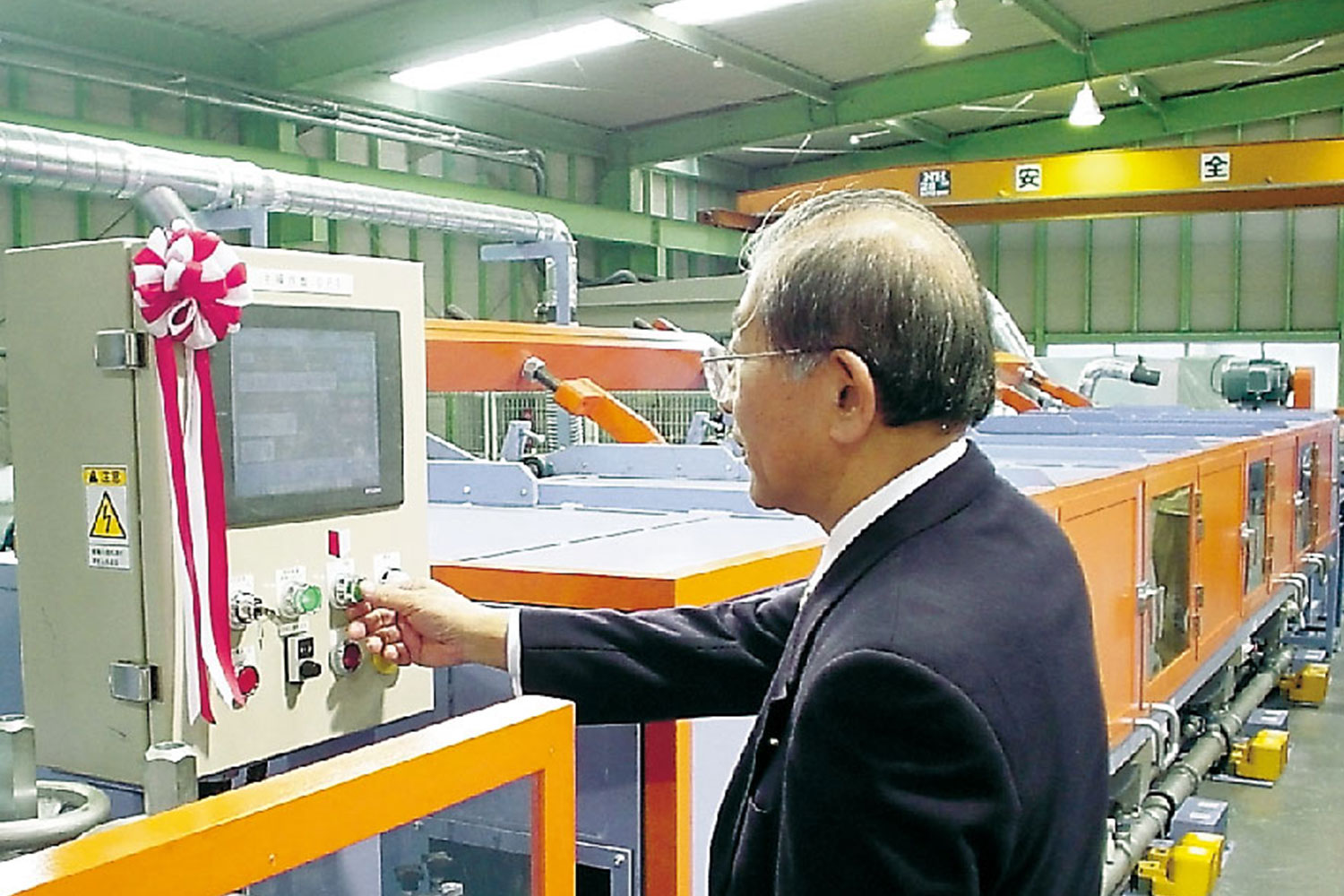

Installed FCW manufacturing equipment (2004)

Established Local Affiliated Company in Dalian, China (2007)

Established Local Affiliated Company in Dong Nai, Vietnam (2011)

Received certification of conversion to ISO 9001 quality management system standard certification from LRQA

Achieved 200,000 t production volume of coated electrodes

FCW obtained JIS Z 3313

Expanded the scope of ISO 9001 to cover the whole company including FCW

Received ISO 14001 Environmental Management Systems certification from LRQA

On to the next era

Since SWECO was established in 1947, we have been supported by many customers. As the times change, the environment surrounding welding also changes and the creation of the next value is required. In addition to the technology and experience that we have accumulated up to now, we work hard to get hold of the latest information and respond to the fine details. We aim to work with you all towards a better future.